Jim Phelan, who owns the Laubin oboe company, has a neat white mustache and sparkly hazel eyes that make him look like a mid-management Santa. Recently surveying his small, busy workshop 60 miles north of New York City, he called it his “island of misfit toys.”

I wasn’t sure whether he meant the work or the workers. At a computer-guided lathe, a burly, bearded man who plays bagpipes in his spare time turned blocks of a tropical hardwood into sexy little batons and flared bells. At a desk beneath a task light nearby, a key maker who just completed aircraft maintenance training worked intently on what looked like rubber buttons. Elsewhere in the bunkerlike space, elves in strappy aprons fiddled with silver, springs, loupes, cork, wax, feathers, fire.

With its collection of oddballs doing oddball things amid a dense canopy of oddball tools, the workshop felt more like a family hardware store after a twister than a sensible instrument manufactory. I found it hard to believe that anything as beautiful and persnickety as an oboe ever escaped its chaos until the operations manager, who also sells real estate, grabbed an instrument from the desk of a finisher and tossed off a test run of sweet, gorgeous Bach.

What then seemed hard to believe was that anyone was ever willing to live without such a sound, and thus without the bizarre, expensive machines that make it. The haunting Act II theme from Tchaikovsky’s “Swan Lake” and the jaunty peeping of Sonny & Cher’s “I Got You Babe” do not come cheap; Laubins start at $13,200.

And yet American classical culture and the artisanship that produces it have been in steep decline for decades. Orchestras disband, school music programs get the ax, instrument makers shut down or move offshore. Within that shrinking niche, oboes may be a niche too far. When Phelan bought the essentially bankrupt Laubin in 2022, any sane accountant would have declared the business unrevivable.

Phelan, 74, is not that accountant. He’s had decades to hone his faith in reinvention. A French horn player since his bumpy Boston childhood, he’d also done time as an instrument repairman, a cabdriver (until a fare put a knife to his throat), an engineer, a business school lecturer, a flute maker, a husband (twice), a divorcé (twice) and a father of three. An inveterate tinkerer, he’s the kind of guy you’d ask to solder your busted brass lamp.

“Anything broken really annoys me,” he said. “But getting something to work turns me on.”

WITH LAUBIN — OFFICIALLY A. LAUBIN LLC — that will not be easy. The oldest and perhaps last substantial American company specializing in professional oboes, as well as their sultrier sisters, English horns, the firm had for years been coasting on its name. Even so, preventing the extinction of what he calls a “gem of American manufacturing” was a pressing enough problem to lure Phelan back from a pleasant retirement in Australia. Now he finds himself an oboe evangelist in a world where few people even know what it is.

I, alas, do. Having mangled the instrument for 10 years of my youth, and possibly mangled my youth with it, I can tell you that it is a woodwind consisting of a reed, a top joint, a bottom joint and a bell. More technically: It is torture.

“The damn instrument was invented by a sadist,” Alison Fletcher, who plays with the Hudson Valley Symphonic Wind Ensemble, told me. “You sound like a wild duck for at least the first three years.”

Frank Swann, administrative director of the International Double Reed Society, also known as the International Double Nerd Society, agreed that the oboe is the most difficult woodwind: “really awkward technically, fingering-wise, every-wise.”

The “double reed” in the name of Swann’s organization is part of the problem: You basically blow air at high pressure through tightly pursed lips into a tiny lentil-shaped opening between two pieces of dried grass to make them vibrate. And if doing that doesn’t mark you as an outcast — or give you a stroke, as has happened more than once — the confounded reed-making process, which involves scrapers and thread and takes more years than there are in life to master, is even worse.

And yet if you ever do get your lips to do what they should, and if your fingers ever figure out how to form the proper crabby clusters on the bewildering assortment of nearly 50 keys, you may find yourself making a piercing yet solacing noise like that of no other instrument.

Over the centuries of the oboe’s evolution from Greek and Roman forebears, that double personality has earned it nicknames suggesting a wide range of emotion: “the melancholy reed” but also “the sprightly companion.” More recently its reputation for wonkiness and honkiness — in “Peter and the Wolf,” the oboe plays the duck — has earned it yet another: the ill wind that blows no good.

Laubins, however, were long prized for their beauty of tone. The website oboes.us, run by Peter Hurd, a fine instrument dealer unafraid to brand some brands “worthy of the ash heap,” praises many older Laubins as “sensational,” with a “smooth, dark, slightly ‘covered’ sound” quite distinct from the sparklier timbre of the world-leading French brand, Lorée. A midcentury oboist who played an American instrument likely played the “American”-sounding Laubin.

Perhaps that’s because the company, named for its founder, Alfred Laubin, was a super-high-end atelier, less about commerce than craft. In 90 years, only 2,050 Laubin oboes were produced. Alfred made the first, in 1931, by cranking a hand-held drill to create the bore and, according to legend, melting his wife’s silverware to fashion the keys. His son, Paul, continued the family tradition, blowing pipe smoke through each new joint to test for cracks. When he died, in 2021, he was alone in his shop, mid-oboe. He had finished at most four in his final year.

HOW TO TURN A PROFIT on what are essentially handmade sculptures that sing remains quite a puzzle, yet Phelan is determined to solve it. He’s loved performing since he was handed his first horn in fourth grade, but it was earning $60 playing two-hour gigs a few years later, sight-reading show tunes in a North End gazebo, that really “incentivized” him. His father’s music career, as a high school band director whose distaste for authority led to frequent relocations and a nervous breakdown, was not, Phelan said, rewarding. “But mine has been.”

So having paid the Laubin family $250,000 and cleared the company’s debt, he set about professionalizing the operation. He bought the new workshop and a house 200 feet away. He began making drawings, eventually more than 4,000, to specify processes that were previously not much more detailed, he said, than “beat a piece of metal until it looks like a key.” With his background in both business and instruments — his flutes, under various names, were successful — he thought he could fix things fast.

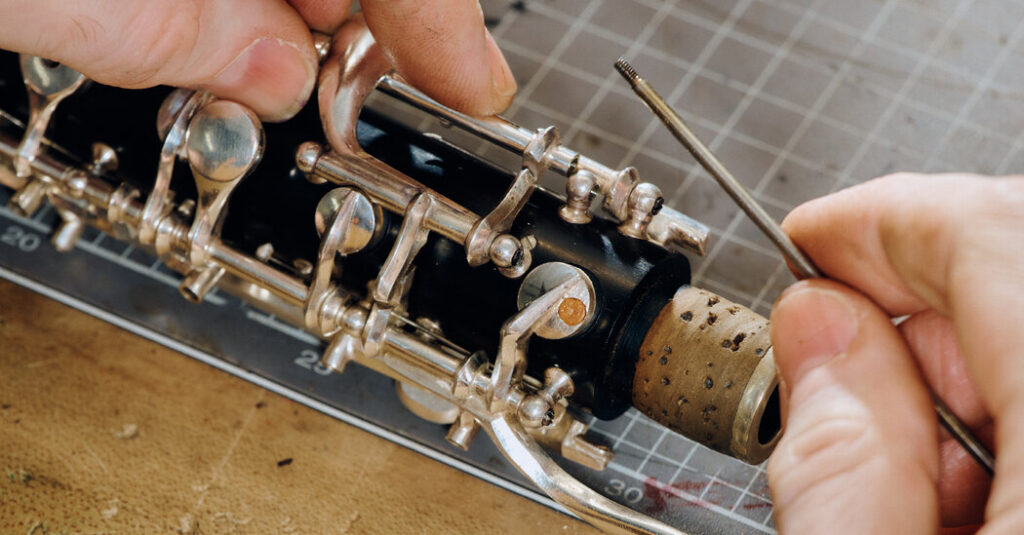

Four years later, having poured another $750,000 into the effort — some of it to defend the company in a surprising legal dispute — the job has proved harder than expected. For one thing, the oboe is way more complicated than the flute. Hurd, the oboes.us webmaster, told me that the instrument, with 500 or so parts that must be perfectly fitted, is “by far the most complicated in the orchestra, mechanically and in terms of engineering.” The real astonishment is not that anyone makes good ones, he added, but that “anyone who makes them breaks even.”

The retooled A. Laubin doesn’t, yet. Though sales in 2024 totaled about $380,000 — more than 10 times the figure in 2022 — it will take $100,000 more to get into the black.

Phelan has a plan.

FOR OBOISTS, the unpredictability of their instrument, given to sudden possession by screeching imps and wobble goblins, offers something besides reeds to focus their anxieties on. What worries them most is that the wood, especially the top joint, might crack, or go bad from the inside, ruining the instrument.

Manufacturers have tried to address the threat. Most high-end modern oboes, including Laubins, have a PVC sleeve tucked into the top joint to protect the bore from saliva and sweat. This may mitigate the problem but not the players’ fear of it. And though synthetic oboes don’t crack, they often don’t sound right. Hurd calls one manufacturer’s composite “very brassy,” which is not, to an oboist, a compliment.

Laubin has traditionally taken a different approach. By far the longest step in its manufacturing process is the weathering of raw wood billets in a shed unprotected from heat, cold and humidity. The first banishment lasts at least eight years. Next, Stephen Gara, the “wood guy,” drills a bore through the billet and sends it back to the shed for two more. Only then is it deemed mature enough to shape on the new $60,000 lathe, which can turn a bell in 20 minutes instead of the day it took in the old Laubin shop.

“I make the oboes,” Gara said proudly. “All the other guys” — he pointed to Scott Bernitt, the key maker who’s also an airplane mechanic, and Todd Kennedy, the finisher with a sideline in wedding cake sugar work — “just put things on them.”

But conservation efforts in Africa and Central America, where the grenadilla, rosewood and cocobolo used in Laubin oboes are grown, keep the price rising. New import tariffs surely won’t help. And even with the best technicians, most of the wood winds up as sawdust anyway.

Finding those technicians has proved to be another headache. When Phelan bought the company, he hired Alex Laubin, 48, who had entered the family business in 2003. Having worked beside his father, Paul, he’d witnessed an attitude toward the process that “approached the religious,” he told me. “He wouldn’t make any changes because if you did it might ruin everything.”

Phelan has no such reluctance to change. He fired Alex two years after hiring him.

What happened is the subject of a claim of unlawful termination that Alex filed last year with the National Labor Relations Board. In it, he asserts that Phelan violated a law that protects the right of employees to discuss “wages and/or other terms and conditions of employment.” During a phone call he put it more bluntly: “I was fired for writing an email to the staff calling for better leadership.”

Phelan’s response to the N.L.R.B. countered that Alex was terminated for poor “work performance” and for failing “to follow explicit instructions given by management.”

The suit has been dismissed twice, first by the regional office, and then, after Alex appealed, by the federal one. On Jan. 5, he appealed again.

PHELAN GOT AN EARLY CHRISTMAS GIFT last month. “Our first Laubinite top joint is finished,” he texted me on Dec. 23. “Could be a game changer.”

I had not heard of Laubinite previously because it had not previously existed. It turns out to be an extremely resilient injection-moldable composite that is engineered to mimic grenadilla and thus its exact sonic profile. Several prototypes had just arrived at the shop, where the elves busily drilled, keyed and finished them. Now they were ready to play.

Phelan’s plan is to open a new revenue stream with the Laubinite top joints, introducing them at $4,700. Players who already own Laubins and want the security of an emergency backup or a standby for use in extreme environments are the obvious market. First-time buyers can also be upsold. Eventually there’s the possibility of entirely Laubinite instruments.

Purists, wedded to wood, may squawk. “I know there will be resistance,” Phelan said when I reached him the next day. “But musical instruments are not invented, they evolve. If you produce better, newer products, players will beat a path to your door.”

Indeed, in a year or two, he hopes to introduce another innovation by reintroducing an old Laubin model: the Barre, produced from 1972 to 1985 and named for Alfred’s mother. The Barre is a mid-market wood oboe suitable for students and amateurs at about half the price of a professional instrument.

Will new materials and marketing be enough to preserve tradition at A. Laubin LLC? Or will they irreparably damage the brand?

Phelan answered sideways. “I go to the Episcopal Church in Somers,” he said, referring to a town nearby. “And the wonderful priest there, she says, ‘Better to do something good than something big.’”

I wasn’t sure what that meant until Ruthie Garcia, the operations manager, attached one of the Laubinite top joints to the bottom joint and bell of a grenadilla oboe, which it matches, and gave it a go. She found it “far closer” to wood in color and warmth than any other synthetic she’d tried. My ears, soiled from years of bad playing, could not detect any difference at all.

But I could certainly detect, a few moments later, a difference in resilience. Phelan took two of the new joints and threw them hard against the concrete floor, as many an oboist has wanted to do but not dared. They tinkled merrily and bounced around. I picked one up. Not a scratch on it.

Jesse Green is a culture correspondent for The Times.

The post Can the American Oboe Sing Again? appeared first on New York Times.