Automotive design studios are magical places.

Often found hidden behind two or three levels of locked doors, accessible only to a chosen few with the right credentials, they’re expansive, well-lit and full of wonder. Mood boards filled with fashion photos, pictures of landscapes and architectural iconography inspire the team. Models of cars sculpted from clay — in various shapes and sizes — fixate the designers.

Then you smell the sulfur.

Traditional modeling clays contain sulfur, a reliable binding agent for the waxes and oils used during the sculpting process, and exudes a pungent smell of rotting eggs. For decades, designers just dealt with the smell until their computers started failing.

“Over 15 years ago, all computer circuit boards switched to a silver compound from lead solder,” said Mark Malewitz, president at Clay Warehouse. “They found out pretty quickly, as any modeler that wore silver jewelry already knew, that sulfur corrodes silver.”

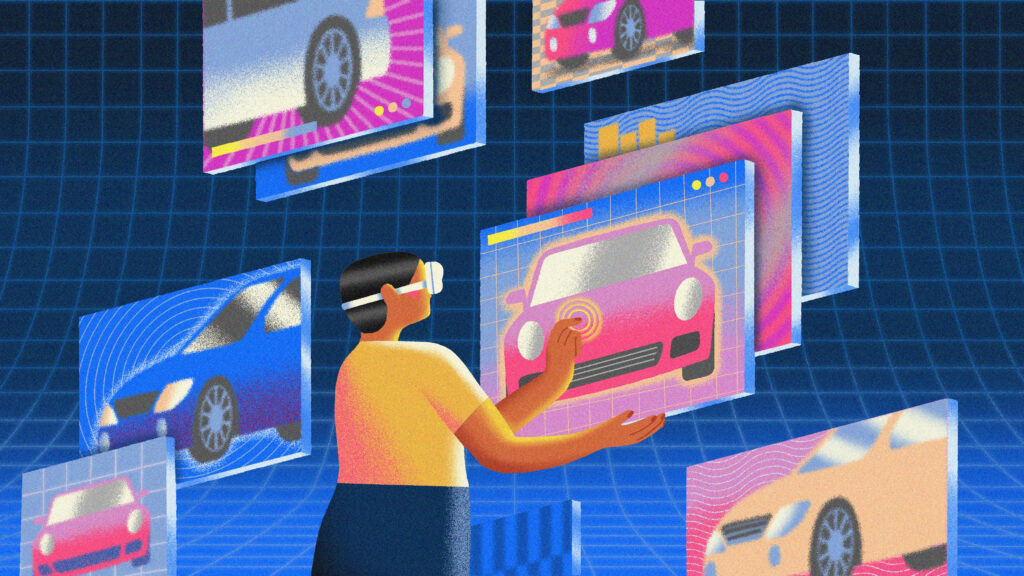

Over the years, some companies such as Chavant and Staedtler have created different formulations without sulfur to try to eliminate the concomitant odor but new technology such as augmented and virtual reality is significantly reshaping the auto development process. Virtual reality headsets, when combined with digital modeling software, allow designers and engineers to collaborate more quickly and easily. Besides saving money, the technology also reduces the need to sculpt full-size models of cars with clay.

“Before we had virtual reality we were building, for a major project, let’s say a new architecture, around about 80 to 100 vehicles,” said Karsten Garbe, plant director at GM’s Artisan Innovation Center in Warren, Michigan. Today, that number is closer to 30 or 40 vehicles, and virtual reality is used in the development of every new car.

From gaming headsets to 3D printing

Like many other auto manufacturers, General Motors first started experimenting with the computer-gaming-focused HTC Vive headsets in the late 2010s. Today, manufacturers use everything from consumer-grade headsets, like Meta’s $499 Quest 3, to more professional units like the Varjo XR-4, which can cost more than $10,000.

Garbe’s team is responsible for piecing GM’s prototype cars together for brands such as Chevrolet and GMC, making sure not only that everything fits but that it can be assembled and serviced in a safe, repeatable way. It’s a little like assembling the world’s most complicated model kit, long before the instructions get written.

Before GM invested in virtual reality, engineers had to wait for prototype components to be manufactured and delivered. Now, they can work from early digital 3D models, checking fit and feasibility months before the first part is cast. Garbe said that this identifies problems early, flagging components that can’t physically be maneuvered into place or that don’t fit properly, dramatically reducing the number of prototype vehicles needed. This process was used to develop GM’s latest electric vehicles, including the Chevrolet Blazer EV and Cadillac Escalade IQ.

When it comes to visual design— the outright style and appearance of the car — there are considerable advantages, too.

Jim Conner, director of 3D process delivery at Ford Design, cited the important task of finding the right wheels. He said designers might go through as many as 35 potential wheel designs for a major model like the Mustang. In the old days, all 35 would have to be crafted by hand from plastic, foam and paint for evaluation.

Using augmented and virtual reality, designers can narrow it down much more quickly, changing colors, finishes and shapes instantly. “We’re really getting down to five or six critical ones that really resonated. And then we’ll actually make very nice prototypes of those,” Conner said

Other technologies, like 3D printing, are changing the game too, speeding up prototyping and the creation of parts out of plastic, resin or even metal that previously would be meticulously hand-sculpted. “We used to hand model, in clay, seats, including stitches,” Conner said. “You can imagine the technique and the expertise it takes to model a stitch on a seat in clay.”

Larger digital designs can also be brought into reality via milling machines that hone giant slabs of clay into a rough shape. The artisan modelers then come in to finesse the final shapes and details.

“The ability to rapidly mill full-size physical models provides significant advantages in the product development process, primarily by enabling a more dynamic approach to design iteration and validation,” said John Krsteski, senior chief designer for Genesis North America.

“We still do hand modeling, but we’ve taken our clay modelers and put a lot of technology in their hands now, and basically given them different tools,” Ford’s Conner said. “We’re trying to not say that people are clay modelers. They’re actually a model maker where clay is one thing they’re using.”

“A lot of the studios were saying, ‘Let’s just go digital,’” Malewitz said. But the results, he continued, weren’t good, with plenty of “angular lines that don’t have the human touch.”

While the engineers can create near-photo-realistic renderings of objects in augmented and virtual reality, a key part of the process was missing: “The one thing you cannot replace with virtual reality is sunlight,” Malewitz said, echoing a common sentiment among designers that, while they may be investing in fewer models than before, nothing beats a real, full-size clay sculpture for final approvals.

“Virtual and augmented reality are really fantastic developmental tools, but I do believe there will always be a point where you’re going to see a physical thing,” Conner said. “I don’t think virtual reality will replace that.”

Tim Stevens is an automotive and technology journalist based in New York, writing for The Verge, Car and Driver, amongst others. He previously served as editor-in-chief of Engadget and CNET’s Roadshow.

The post How to design a new car in 2026 appeared first on Washington Post.